Table of Contents

Unimatic CNC Router

- Isel C142 controller

- plugged into a laptop running LinuxCNC

Status

In use, but there are some tasks that still need to be done to make it better (E.g. touchoff pad):

Usage Notes

Ideally this section should be a step-by-step guide, but for now, it's just some key notes on the CNC's quirks.

The spindle is watercooled. The cooling unit has a flow sensor which is wired into the e-stop loop - this will stop the machine if the pump ever fails.

The CNC laptop runs Debian 7 and should not be updated as the CNC functionality relies on a special realtime kernel which is (in technical terms) a royal pain in the arse to set up.

The out-of-date OS means the laptop can't access network shares. Load your gcode files using the SD card reader in the front of the laptop.

Gcode files need to have a “.ngc” file extension. The last line of the gcode should be “M30”; this is a programme end signal and LinuxCNC will refuse to load any files without it.

The step blocks and clamps we have at the moment are 3D printed. Don't push the machine too hard while using these. If you want to mill thick metal at high speeds, you'll need a metal clamping set; the lab has discussed purchasing a set like this one in the past and there should be no problem doing so if anyone needs them.

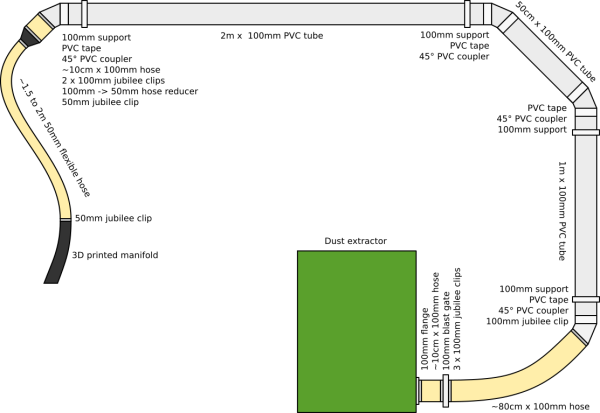

Ducting (Finished)

Ducting plan:

We have 100mm hose and 50mm jubilee clips in stock. Remaining things to buy:

Axminster £14.34:

ducting-online.co.uk £99: